Wasserstoff ist der ideale Energieträger. Er kann auch leicht mit erneuerbaren Energien hergestellt werden und ist in großen Mengen vorhanden. Wird er verbrannt, entstehen keine Schadstoffe.

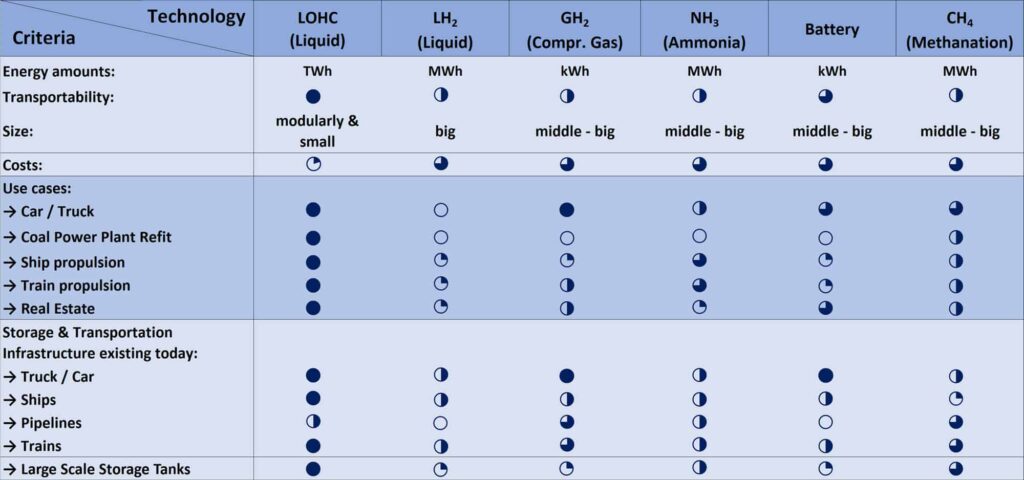

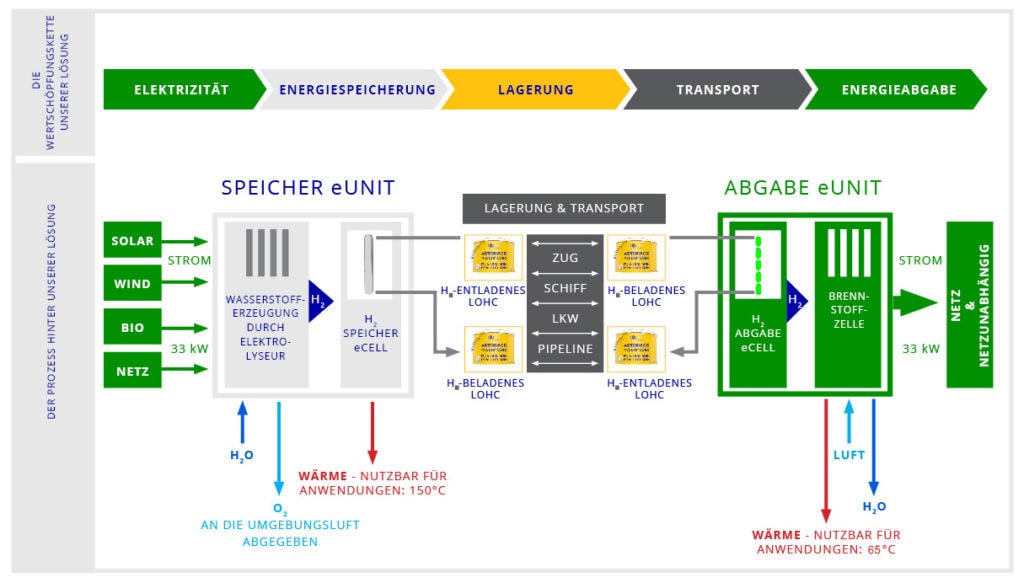

H2-Industries baute darauf auf und entwickelte eine Lösung, die den Strommarkt revolutioniert: Die innovative LOHC-Speichertechnologie macht den Umgang mit dem Energieträger Wasserstoff völlig sicher. Das Gas kann nun risikolos und in großen Mengen gespeichert, transportiert und wiederverwendet werden.

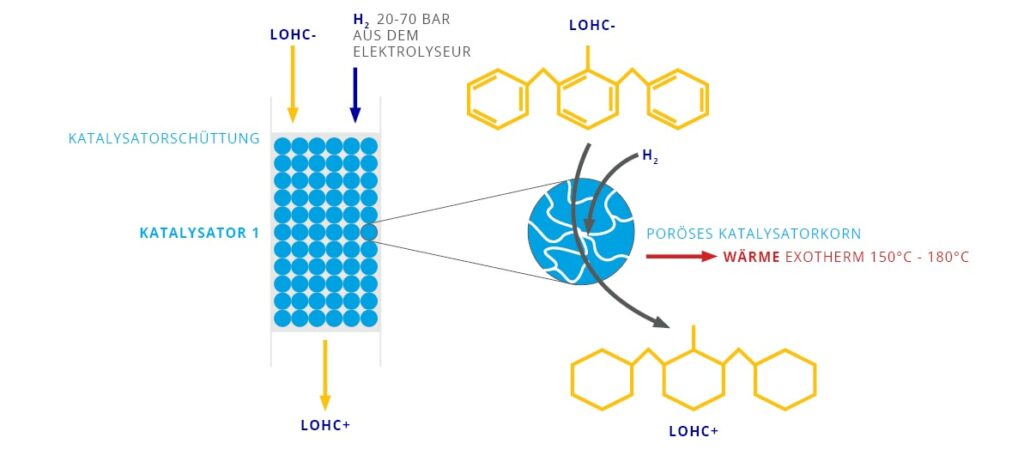

Die LOHC-Technologie beruht auf Liquid Organic Hydrogen Carrier, einer ölartigen organischen Substanz, die Wasserstoff chemisch bindet. Verschiedene Substanzen sind dafür denkbar, H2-Industries nutzt Dibenzyltoluol, das in seinen physikalisch-chemischen Eigenschaften dem Diesel sehr ähnlich ist. Die chemische Speicherung von Wasserstoff im LOHC ermöglicht eine Lagerung unter Umgebungsdruck (p = 1 bar) und Normaltemperatur (T = 20° C). Ein weiterer Vorteil ist, dass der so gespeicherte Wasserstoff nicht flüchtig ist und somit auch keine Selbstentladung stattfinden kann. Das LOHC kann beliebig oft mit Wasserstoff be- und entladen werden.